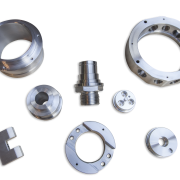

CNC machining

.

Our company has mainly specialised in medium and small batch production in CNC manufacturing including CNC forging and we are open to orders with short deadlines. With 18 years of expertise in CNC machining we are dedicated to serve you with the latest production technology striving for the highest quality.

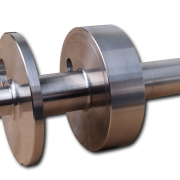

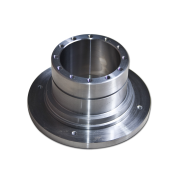

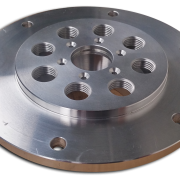

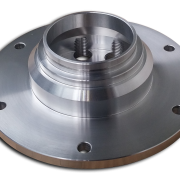

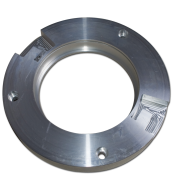

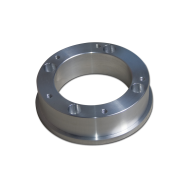

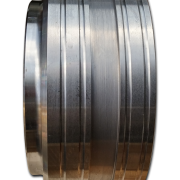

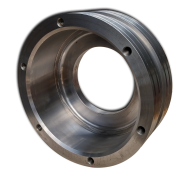

Most of our jobs are coming from parts manufacturing for public transportation vehicles. Our product range contains brake and powertrain components used for delivering high torque that necessarily have to meet the numerous safety requirements.

Engineering and technical drawings are made by CAD software and production is supported by CAM software. Our workshop is equipped with state-of-the-art technology that is capable of accomplishing special manufacturing assignments. Five lathe machines and three machining centres constitute the core of our production capacity made by German SPINNER and DMG Mori Seiki. All of our machines entered service as new.

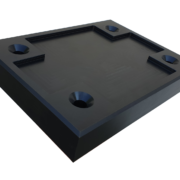

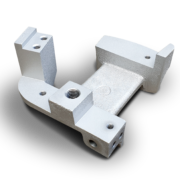

Our latest product development is a sport equipment family dedicated for fitness and therapy areas under smartCircle brand. This product line is currently in the launch phase. All parts our manufactured with our CNC machinery and completely assembled in our plant.

EVOLVENS (evolvens.com) watch is a special reference for us in making parts with precision CNC manufacturing. Attention to detail and careful handling are needed due to the high aesthetic requirements.

Our quality assurance is based on ISO 9001:2015 standards.

Materials we work with: steel, stainless steel, aluminium, brass, copper, plastic, textile vinyl and others

Production features

Lathes

- bar capacity: max. 65 mm

- lathing diameter: max. 500 mm

- lathing lengths: max. 700 mm

- axially and radially powered toolstwo-spindle lathebar feedingSiemens computer control

Machining centres:

- maximum size: 800×600 mm

- maximum axle capacity: 12.000 RPM

- 4 axis

- Siemens computer control

Our strengths

- Outstanding expertise, 18 years experience with CNCs

- flexibility, small-batch series production

- high-precision machining, quality guaranteed

- punctuality and reliability

- competitive prices

Milestones

1989 – beginnings of machining

1994 – moving to new company premises and expanding lathing capacity

2003 – starting CNC production

2006 – establishing a new CNC unit and 6th new machine utilised

2009 – two-spindle CNC machine put into production

2014 – the newest, 8th CNC machine enters service

2021 – the relocation of the entire production capacity to a brand new, modern plant by the end of 2021